Ambala Cantt, Haryana

- GST NO. : 06ALMPG8235A1ZD

| Business Type | Manufacturer, Exporter, Trader, Importer |

| Country of Origin | India |

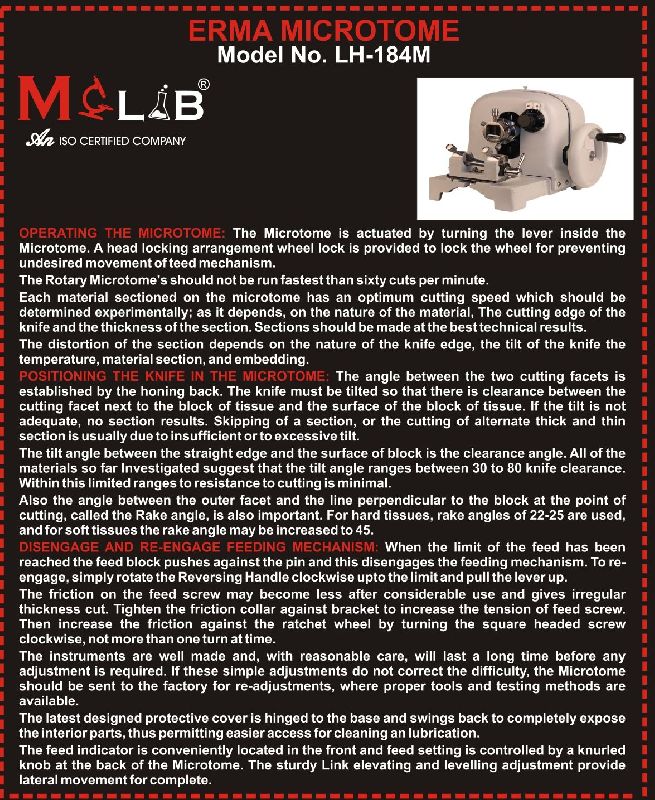

| Type | ERMA Micortone |

| Application | Laboratory |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

OPERATING AICRCITCIM

The Microtome is actuated by turning the lever inside the Microtome. A head locking arrangement wheel lock is provided to lock the wheel for preventing undesired movement of teed mechanism. The Rotary Microtome's should not be run fastest than sixty cuts per minute. Each material sectioned on the microtome has an optimum cutting speed which should be determined experimentally; as it depends, on the nature of the material, The cutting edge of the knife and the thickness of the section. Sections should be made at the best technical results. The distortion of the section depends on the nature of the knife edge, the tilt of the knife the temperature, material section, and embedding.

POSITONING THE KNIFE IN THE MICROTONE

The angle between the two cutting facets is established by the honing back. The knife must be tilted so that there is clearance between the cutting facet next to the block of tissue and the surface of the block of tissue. If the tilt is not adequate, no section results. Skipping of a section, or the cutting of alternate thick and thin section is usually due to insufficient or to excessive tilt. The tilt angle between the straight edge and the surface of block is the clearance angle. All of the materials so far Investigated suggest that the tilt angle ranges between 30 to 80 knife clearance. Within this limited ranges to resistance to cutting is minimal. Also the angle between the outer facet and the line perpendicular to the block at the point of cutting, called the Rake angle, is also important. For hard tissues, rake angles of 22-25 are used, and for soft tissues the rake angle may be increased to 45.

DISENGAGE AND RE-ENGA% EEDING MECHANISM

When the limit of the feed has been reached the feed block pushes against the pin and this disengages the feeding mechanism. To re-engage, simply rotate the Reversing Handle clockwise upto the limit and pull the lever up. The friction on the feed screw may become less after considerable use and gives irregular thickness cut. Tighten the friction collar against bracket to increase the tension of feed screw. Then increase the friction against the ratchet wheel by turning the square headed screw clockwise, not more than one turn at time. The instruments are well made and, with reasonable care, will last a long time before any adjustment is required. If these simple adjustments do not correct the difficulty, the Microtome should be sent to the factory for re-adjustments, where proper tools and testing methods are available. The latest designed protective cover is hinged to the base and swings back to completely expose the interior parts, thus permitting easier access for cleaning an lubrication. The feed indicator is conveniently located in the front and feed setting is controlled by a knurled knob at the back of the Microtome. The sturdy Link elevating and levelling adjustment provide lateral movement for complete.

Looking for "ERMA Micortone" ?

Explore More Products